Recently Viewed

Just a couple more seconds...

RG-400i-3PH is Hallde’s largest and most effective Vegetable Preparation Machine that prepares very large volumes, up to 3,000 portions/day or 2.4 tons/hour. The cutting tool range is broad; cuts, dices, shreds, cuts julienne, crimping slices and cuts French fries in a wide range of dimensions. There is a broad range of feed attachments and accessories, enabling adaption to many different needs.

RG-400i is a floor model, with a compact shape, of high quality, manufactured in stainless steel, ergonomic and very easy to clean. The cutting tools, feeders and accessories can be cleaned in the dishwasher. RG-400i fulfils all of the requirements that are placed on a professional Vegetable Preparation Machine independent of which environment it is used in: restaurants, large sized kitchens, industrial environments, catering or as a part of a production system.

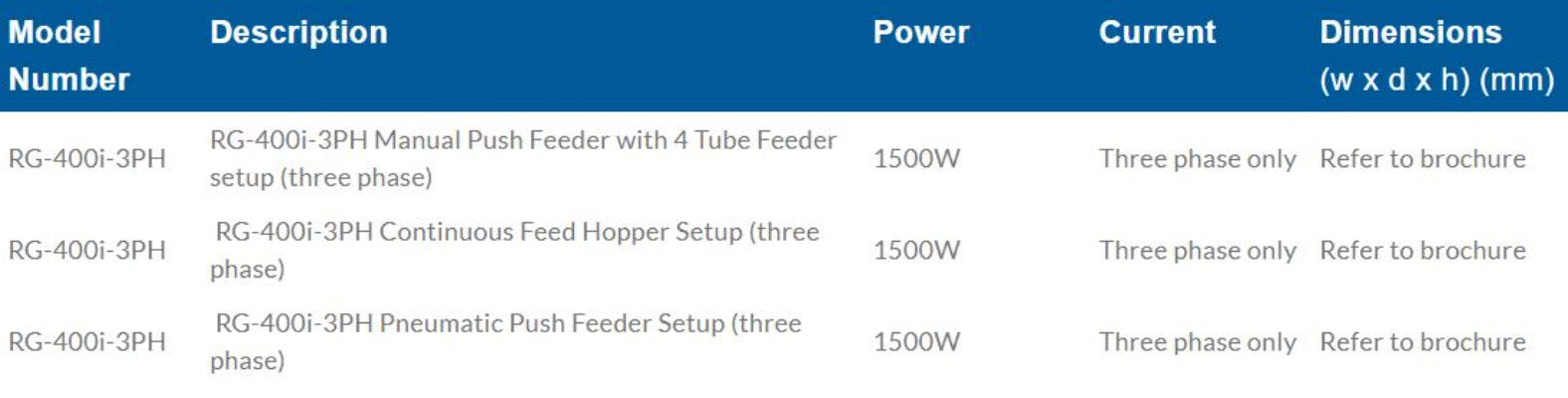

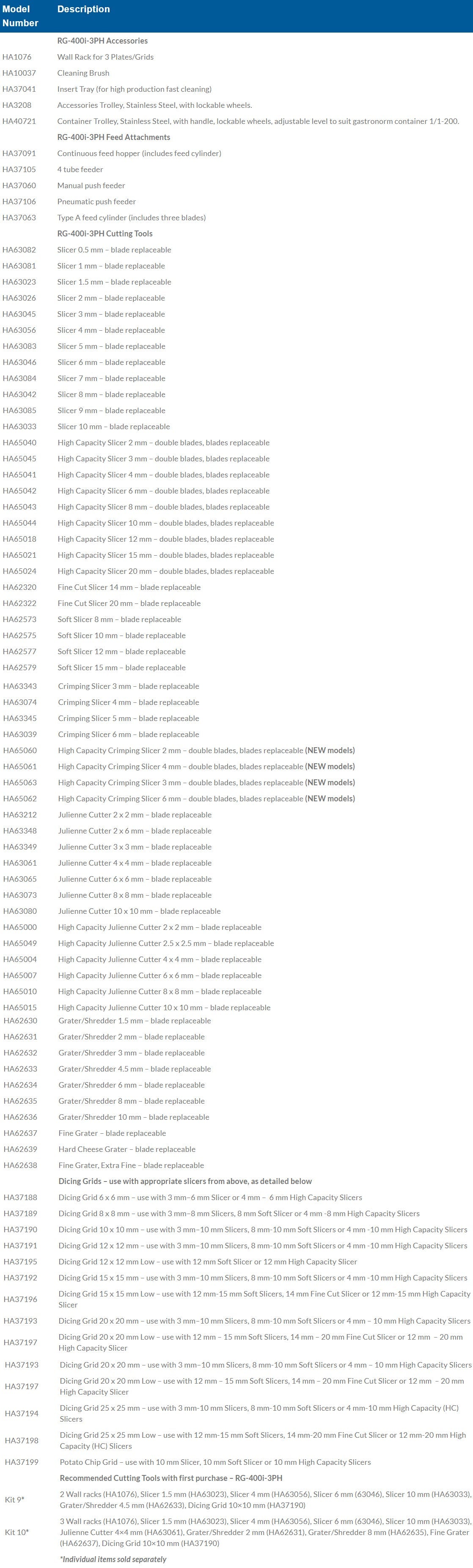

Models:

RG-400i-3PH MANUAL PUSH FEEDER WITH 4 TUBE FEEDER SETUP (THREE PHASE)

Food manufacturing capacity vegetable preparation. Make more than 50 different cuts. Slice, crimp, julienne, shred/grate, dice & potato chip.

Processes up to 5,000 portions/day, 60 kg/minute or up to 3.6 tons/hour.

RG-400i-3PH CONTINUOUS FEED HOPPER SETUP (THREE PHASE)

Food manufacturing capacity vegetable preparation. Make more than 50 different cuts. Slice, crimp, julienne, shred/grate, dice & potato chip.

Processes up to 5,000 portions/day, 60 kg/minute or up to 3.6 tons/hour.

RG-400i-3PH PNEUMATIC PUSH FEEDER SETUP (THREE PHASE)

Food manufacturing capacity vegetable preparation. Make more than 50 different cuts. Slice, crimp, julienne, shred/grate, dice & potato chip.

Processes up to 5,000 portions/day, 60 kg/minute or up to 3.6 tons/hour.

Overview:

Perfect cutting results

RG-400i-3PH has a broad range of cutting tools that cut, dice, shred, cuts julienne, crimping slices and cuts French fries in a wide range of dimensions and prepares both hard and soft products. The cutting tool’s large diameter of 215 mm in combination with the spacious feed cylinders means that RG-400i-3PH can handle very high volumes at each fill. The rotation speed of the cutting tool is optimised to make even cuts as effectively as possible. The knives are ground according to purpose in order to retain their sharpness for a long time and are available as spare parts when it is time to replace them. The machine has two speeds – 200 rotations/minute and 400 rotations/minute.

Best hygiene

All removable parts are manufactured in stainless steel and can therefore be washed in a dishwasher. The machine base, also in stainless steel, has smooth surfaces, rounded edges and lacks unnecessary recesses into which food can penetrate and get stuck. When the stainless removable tray is used, cleaning is facilitated even more because it can easily be taken out of the knife housing and cleaned in the dishwasher. In this way the machine base itself is kept free from the products that are being prepared. Thanks to the distance of 150 mm between the machine and the floor it is also easy to clean the floor under the machine. With help of the sturdy handle and the robust wheels on two of the machine’s legs it is easy to move. RG-400i-3PH is manufactured solely of food approved material.

A model safety system

The RG-400i features two safety systems that prevent the machine from running when the cutting tool is unprotected. In order for the machine to start, the feed cylinder must be correctly mounted and the feeder must be in the right position and covering the cutting tool.

Highest possible reliability

The powerful motor is developed to be able to handle long and tough preparation conditions when the machine is used constantly during full work days, for example in a production system and also for repetitive preparation with many starts/stops. RG-400i-3PH has a high torque during start and operation and drives the cutting tool via a maintenance free gear drive made completely of steel. Here there are no intermediate belts that can wear or break, all in order to ensure the highest possible reliability.

Feed Hopper

Enables continuous filling by the bucket for preparation of primarily round products. The capacity becomes very high because the machine runs constantly and is thus extremely time effective. RG-400i-3PH with Feed Hopper can be strategically placed in a continuous production flow.

Manual Feeder

Can prepare all types of products, both large and small. The Ergo-loop design gives a lever effect which also reduces the need for manual force when preparing large and hard products such as root vegetables, cabbage and cheese. For fast and safe preparation, the machine stops when the feeder is moved to the side and starts automatically when it covers the feeder cylinder’s opening.

Pneumatic Push Feeder

Can prepare all types of products, both large and small. With the pneumatic feeder the product is pushed down automatically with just one push of a button. The workload and time spent are minimised and the feeder is therefore particularly useful when preparing larger quantities and when large and hard products are to be cut. Just like the Manual Feeder, the cutting tool stops rotating when the feeder is moved to the side and automatically starts again when the feeder is swung back. The Pneumatic Feeder has three speeds that can be varied depending on what is going to be prepared.

4-Tube Insert

In order to easily be able to cut long and narrow products standing, and round products in a special direction, the 4-Tube Insert is used. The feeder has four tubes with the following diameters: 73 mm (two tubes), 60 mm and 35 mm. The tubes give good support for products in a range of different sizes, such as cucumber and leeks. In the tube it is also simple to “bunch together” herbs and parsley, etc. When the 4-Tube Insert is used the machine runs continuously because the rotating cutting tool is covered by the feeder at all times.

Your easy way to get 3 years warranty

Complete the warranty registration form for all purchases of Hallde Food Preparation Machines in Australia and you are entitled to a 24 month warranty extension. This extension increases the warranty of your machine to three (3) years parts & labour. (Standard warranty is one (1) year parts & labour). Terms and conditions of the warranty applicable at the time of purchase apply to this Warranty Extension. Please refer to these original warranty conditions set out in the Owners Manual supplied with your machine.

Warranty Application Process

The extension application form must be completed and returned to Hallde within 30 days of purchase. Send the form, including a copy of your purchase invoice direct to Hallde in Sweden.

Features:

The RG-400i-3PH is Hallde’s largest and most effective Vegetable Preparation Machine that prepares very large volumes. The cutting tool range is broad – slices, dices, shreds, cuts julienne, crimping slicers and cuts french fries in a wide range of dimensions. There is a broad range of feed attachments and accessories, enabling adaptation to many different needs.

RG-400i-3PH MANUAL PUSH FEEDER WITH 4 TUBE FEEDER SETUP (THREE PHASE)

RG-400i-3PH CONTINUOUS FEED HOPPER SETUP (THREE PHASE)

RG-400i-3PH PNEUMATIC PUSH FEEDER SETUP (THREE PHASE)

If you would like a live demonstration of this product, please let us know and we will be happy to arrange it with the brand manager

See our full range of Hallde Products

See Similar products from Food Processors Category

We know how important it is for your order to arrive smoothly and on time. Our team processes new orders within 2 business days and prepares them for dispatch. Deliveries take place Monday to Friday during business hours.

Estimated Standard Delivery times after courier pickup:

Important:

Before ordering: Always check product dimensions, access points and ventilation clearances.

If a product cannot fit through doorways, halls, lifts or the intended space on arrival, this remains the customer’s responsibility and is handled under our Change of Mind policy.

Measuring in advance avoids delays, extra delivery fees or unnecessary returns.

Orders containing multiple products from multiple brands may be shipped in separate parcels via different carriers and may arrive separately depending on carrier routing.

Tracking numbers may not all appear on your order page due to system limitations. If you need all tracking details, simply reply to your order email and we’ll send them within 1–2 business days.

We will help monitor progress and ensure everything arrives safely.

Free delivery promotions are available from time to time on selected products and to selected suburbs — typically Melbourne, Sydney and Brisbane metro.

Outer metro areas and Perth may qualify when stock is local to those regions.

Use the Delivery Estimator on each product page to check eligibility for your suburb. If you call us, we’ll confirm it using the same tool before finalising your order.

Need inside delivery or old appliance removal? Please request a Premium Delivery quote.

Request a quote before ordering to confirm feasibility and pricing.

For gas, refrigeration or electrical setup, our installation partners can assist — submit the Installation Form.

Old units must be disconnected and drained prior to removal to avoid extra fees.

We deliver Australia-wide and can arrange international freight on request.

Collection is by appointment only and may take 1–2 business days to arrange depending on brand and location.

Please wait for warehouse confirmation before arriving. Damage during self-transport is not covered under warranty.

Manufacturer's Warranty 2

Experiencing an issue with this product?

If your product is faulty or damaged, please complete this form and we will forward your request to the manufacturer's service department right away

Ordered the wrong product or changed your mind?

Our priority is our customers however we have to respect our suppliers' strict returns policies. We live in a world of high volumes and slim margins to keep prices down. For these reasons, our suppliers charge 25% restocking fees if you change your mind about a purchase or order the wrong item and then want to exchange it for another.

If your order needs to be re-routed or returned to its warehouse(s) of origin after being collected by a courier, many additional people become involved to facilitate your return.

Unless there is transit damage, a manufacturing defect or a mistake on our end, you will be responsible for any re-delivery and restocking fees.

If you have any questions about the product or want to confirm any details at all, please contact us before ordering.

We do not offer returns, refunds, exchanges or credit notes in cases where you have placed an order and you change your mind.

For more information, please see our Returns Information

We know how important it is for your order to arrive smoothly and on time. Our team processes new orders within 2 business days and prepares them for dispatch. Deliveries take place Monday to Friday during business hours.

Estimated Standard Delivery times after courier pickup:

Important:

Before ordering: Always check product dimensions, access points and ventilation clearances.

If a product cannot fit through doorways, halls, lifts or the intended space on arrival, this remains the customer’s responsibility and is handled under our Change of Mind policy.

Measuring in advance avoids delays, extra delivery fees or unnecessary returns.

Orders containing multiple products from multiple brands may be shipped in separate parcels via different carriers and may arrive separately depending on carrier routing.

Tracking numbers may not all appear on your order page due to system limitations. If you need all tracking details, simply reply to your order email and we’ll send them within 1–2 business days.

We will help monitor progress and ensure everything arrives safely.

Free delivery promotions are available from time to time on selected products and to selected suburbs — typically Melbourne, Sydney and Brisbane metro.

Outer metro areas and Perth may qualify when stock is local to those regions.

Use the Delivery Estimator on each product page to check eligibility for your suburb. If you call us, we’ll confirm it using the same tool before finalising your order.

Need inside delivery or old appliance removal? Please request a Premium Delivery quote.

Request a quote before ordering to confirm feasibility and pricing.

For gas, refrigeration or electrical setup, our installation partners can assist — submit the Installation Form.

Old units must be disconnected and drained prior to removal to avoid extra fees.

We deliver Australia-wide and can arrange international freight on request.

Collection is by appointment only and may take 1–2 business days to arrange depending on brand and location.

Please wait for warehouse confirmation before arriving. Damage during self-transport is not covered under warranty.

Manufacturer's Warranty: 12 Months

Experiencing an issue with this product?

If your product is faulty or damaged, please complete this form and we will forward your request to the manufacturer's service department right away

Ordered the wrong product or changed your mind?

Our priority is our customers however we have to respect our suppliers' strict returns policies. We live in a world of high volumes and slim margins to keep prices down. For these reasons, our suppliers charge 25% restocking fees if you change your mind about a purchase or order the wrong item and then want to exchange it for another.

If your order needs to be re-routed or returned to its warehouse(s) of origin after being collected by a courier, many additional people become involved to facilitate your return.

Unless there is transit damage, a manufacturing defect or a mistake on our end, you will be responsible for any re-delivery and restocking fees.

If you have any questions about the product or want to confirm any details at all, please contact us before ordering.

We do not offer returns, refunds, exchanges or credit notes in cases where you have placed an order and you change your mind.

For more information, please see our Returns Information

We have a special page just for stock that's warehoused in Perth.

Click Here to see all WA stock